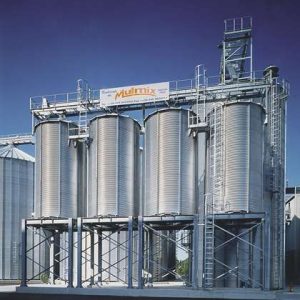

The quick loading silos (CR series) are used for loading means of transport such as trucks and trains.

The cereal is loaded in the silos at the rate provided by the conveyor devices in the plant and unloaded by means of gravity through an automatic or manual shutter positioned at approximately 4.2 meters off the ground.

The use of a quick loading CR silo speeds up vehicle loading, making the cereal always available for delivery including without the use of mechanical devices.

A corrugated metal hopper silo, onto which an unloading cone is fitted, is assembled on a totally hot-galvanised square structure made up of a cone connection ring, supporting legs and braces on two sides. It is anchored to the ground by means of rawl bolts or anchor bolts.

On specific request, only the silo complete with unloading cone can be supplied. In this case, the silo is positioned on a concrete base made according to plant requirements.

The cone connection ring is produced from a calendered UPN profile (UNI EN10025). The supporting legs consist of H beams (UNI EN10025) braced either with angle bars or UPN profiles (UNI EN10025).

The unloading hopper is inclined by 35° for the 3700 and by 45° for the 4600 model and is made from bolted-together hot-galvanised sheet-metal modular elements.

The cylinder is made of corrugated structural steel metal panels in S350 GD (UNI EN10346) structural steel sheets with Z600 galvanised covering (equivalent to 600g/m2 of zinc) that ensures long-term resistance to atmospheric agents.

The cylinder is externally reinforced with HX420LAD (UNI EN10346) structural steel uprights columns with omega section and anchored to the cone connection ring of the supporting structure.

The thickness of the corrugated structural steel panels and of the uprights is defined according to the model and the place of installation of the silo (the solicitations due to seism wind and snow are also considered crucial elements). The calculation of the stresses produced by the silage is made according to EN 1991-4:2006 standards (Eurocode 1, part 4).

The sheets, the uprights, the structure and the cone are assembled using high mechanical resistance bolts, treated with Geomet® process against corrosion. The infiltration of water through the joints between the metal sheets is prevented by inserting a sealing bead.

The standard CR silo is equipped with the following accessories:

• a roof hatch for checking the stored cereal

• air breather on the roof

• ladder for the inspection from the central dome with standing platform anchored on the metal supporting structure of the silo

• manual unloading shutter

Supplied at customer request or according to particular plant requirements

• maximum and minimum level gauges

• motorized unloading shutter

• anchor bolts

• vertical ladder with guards and stirrups

• roof ladder with guards and circular platform

• hanging gangways for inspection and conveyor support

• gangway supporting structures

• descent from gangways

• at customer request, the roof can be painted in customized colors.